|

As with all analog voltage measurements, it's important to avoid voltage offset errors

(this topic is described here).

These errors can occur when two electronic modules have small differences in their ground voltage level.

A Tech Edge controller with a differential output voltage (only some early models didn't have this feature) is the best choice to counteract this effect.

Although most Tech Edge controllers will work, lets assume we use the 2C0 as the sensor controller.

The 2C0 has the advantage of simplicity and small size, and a simple, pluggable, 6-pin screw-in connector to make wiring simple.

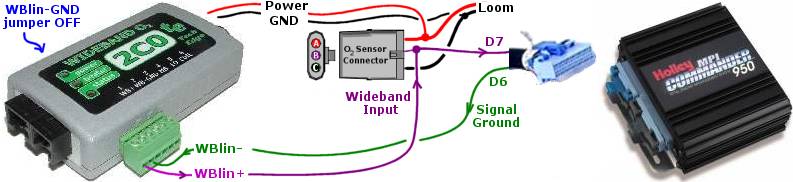

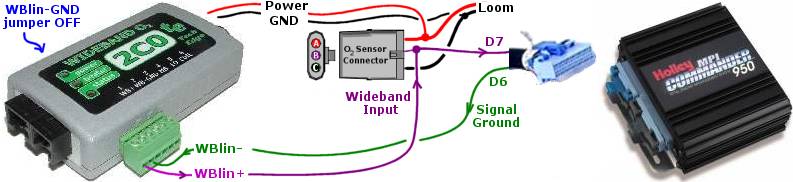

The image below (not to scale) shows how the 2C0 is connected to the HC-950.

Wiring the 2C0's WBlin +/- to the Holley HC-950 Loom

Note that the actual sensor, and cable from the 2C0 to the sensor, are not shown above.

The sensor cable plugs into the back of the 2C0.

A display can be plugged into the black 8 pin RJ45 connector at the left end of the 2C0.

The important things to note above are that:

- The 2C0's WBlin+ signal goes to the purple (centre) pin of the HC-950's oxygen sensor connector (D7).

- The 2C0's WBlin- signal does NOT go to the the GND pin of the HC-950's sensor connector.

it does go to pin D6 of the loom. The wire colour for D6 is described as Black/White.

- Power (red) and GND (black) for the 2C0 can be taken from pins A and C

of the HC-950's oxygen sensor connector.

- The differential output of the 2C0 must be enabled by removing the WBlin-GND jumper inside the 2C0's case.

2C0's and most other Tech Edge controllers are shipped with the differential output disabled because this

configuration gives fewest problems in the field, but it also gives worse performance than having the green WBlin- wire

connected to the analogue ground of the HC-950.

- Note that we have shown the connections to the back of the Holley's wiring loom rather than to the connector itself -

if you have a mating weather pack connector for the Holley loom, then use that to make it easier, but under no circumstances

should you ignore the WBlin- wiring to D6 (Black/White) just because it doesn't have an easy connection option.

Changing the Holley AFR table to Match the 2C0's Output

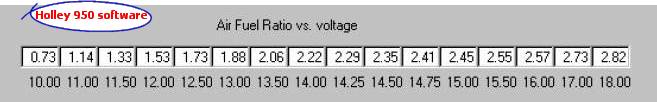

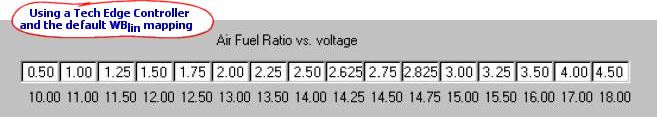

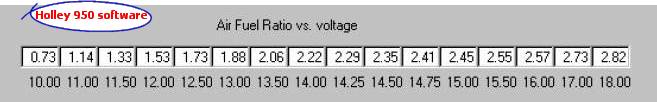

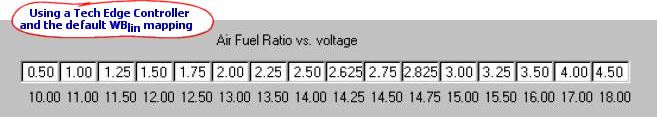

The next thing to do is set up the correct conversion table from Volts to measured AFR within the HC-950.

This table appears in various HC-950 software menus, but they all look and work the same way.

The table above shows the default entries when using Holley's own controller.

The new entries below are simply the tabled version of the graph that appears above right.

Here's a spreadsheet and graph for each table.

Everything is now set up. Remember to read up on how to use your wideband sensor and in particular where to place the sensor.

A tailpipe sniffing position requires special measures to ensure the sensor is not over cooled and

using an existing narrowband sensor bung, close to the exhaust valves, may result in overheating the sensor - see here for more info.

|