|

Although the rev-3 PCB has provision for a press button, a remote button can be added for convenience.

The following paragraphs are most applicable to the rev-2 PCB.

To control logging, the press button switch PB1 can be mounted on the case

somewhere (with short flexible leads), or remotely using a longer cable.

We illustrate below a possible way of attaching a longer cable to the unit.

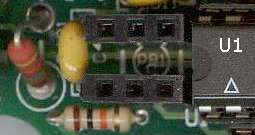

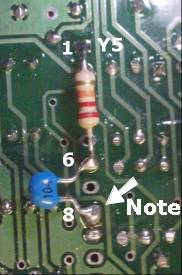

The image at right shows a single core shielded cable wired to Y5 pins 6 and 8.

Note that the shield goes to pin 8 (GND) and is attached to the component side

of the PCB.

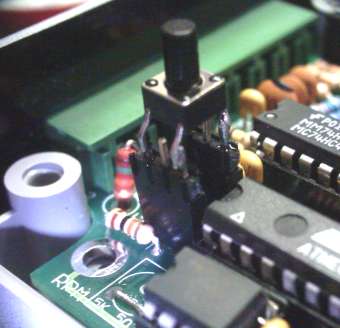

The image montage below shows a way of mounting the remote switch.

The switch in this case is a spring loaded toggle switch.

A conventional press button could have been used.

|

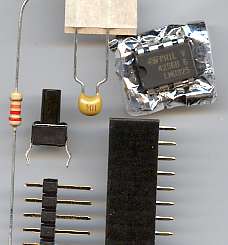

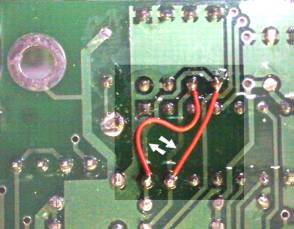

The image at left shows the PB1 assembly with the header strip

before the header is soldered to the PCB.

The image at left shows the PB1 assembly with the header strip

before the header is soldered to the PCB.

<

<